COMPANIES REPRESENTED

Alpine Technology is the Wastewater Representative for these Principals:

Energy Recovery – Air Preheaters, Waste Heat Boilers, Thermal Oil Heaters, Gas to Gas Heat Exchangers

Arvos Schmidtsche Schack LLC (SCS – formerly American Schack Company) designs and manufactures high temperature and special design heat transfer equipment for some of industry’s toughest environments, including corrosives and erosive particulate matter, high pressures, and reducing atmospheres. Applications within the wastewater industry include incineration, Organic Rankine Cycle (ORC), gasification, and drying.

In the municipal wastewater industry, SCS is a long time market leader providing recuperative air preheaters, thermal oil heaters, waste heat boilers and various other gas to gas heat exchangers since 1968.

Recuperation takes place when flue gas is used to preheat combustion air or fuel. In the case of a fluid bed incinerator, the fluidizing air is preheated and this is referred to as recuperation. It is the most common and economical approach to primary heat recovery. Heat is recycled from the flue gas, back to the combustion source, reducing or eliminating auxiliary fuel consumption. For example, in an incinerator operating at 1500°F with 1000°F preheat, the fuel savings can be 25-70%. With an air preheat of 1200°F and a well dewatered sludge, systems can be operated autogenously without the need for auxiliary fuel.

Schack® Waste Heat Boilers and Thermal Oil Heaters are custom designed for the wastewater industry, and with multiple styles and arrangements, boilers and heaters can be catered for different needs.

For additional information, contact Peter Brady at Alpine Technology, and also visit the SCS website at:

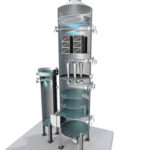

Emission Control – Advanced VenturiPak Scrubber, MercuryPak Scrubber, and Star Wet ESP. Integrated or Stand Alone Solutions.

EnviroCare International is a leading supplier of multi-Venturi VenturiPak scrubbers, MercuryPak scrubbers, and Star wet electrostatic precipitators (WESPs).

The VenturiPak scrubber is a result of re-examining and optimizing the Venturi concept to achieve high collection efficiency at modest energy consumption (i.e. low to medium pressure drop).

The fine particulate fraction in incinerator off-gases is comprised of fine solid particles (<1 micron) and condensed solid and liquid aerosols resulting from the cooling and sub-cooling in the scrubber. These fine particles are problematic in that:

- They are the most optically active, so that even in low concentration, they affect stack opacity.

- They may contain significant concentrations of heavy metals.

- They are most difficult to capture, requiring very high energy for conventional Venturi scrubber systems or the addition of a WESP.

The VenturiPak scrubber eliminates fine particulate with less pressure drop and more efficiency than any other scrubber on the market.

The MercuryPak scrubber can remove volatilized elemental mercury in exhaust gases not capable of being captured in a wet scrubber. This was developed to meet the requirements of the EPA 129 SSI and CISWI regulations, and there are many successful systems in operation.

EnviroCare also has a compact, high velocity advanced Star WESP. The VenturiPak scrubber will usually meet the emission limits by itself, making a follow-up WESP smaller than those sized for traditional wet scrubbers.

Both the MercuryPak scrubber and Star WESP systems can be supplied as integral stages of the VenturiPak scrubber or as stand alone vessels downstream in the process.

For additional information contact Peter Brady at Alpine Technology, and also visit the EnviroCare website at: